About the product

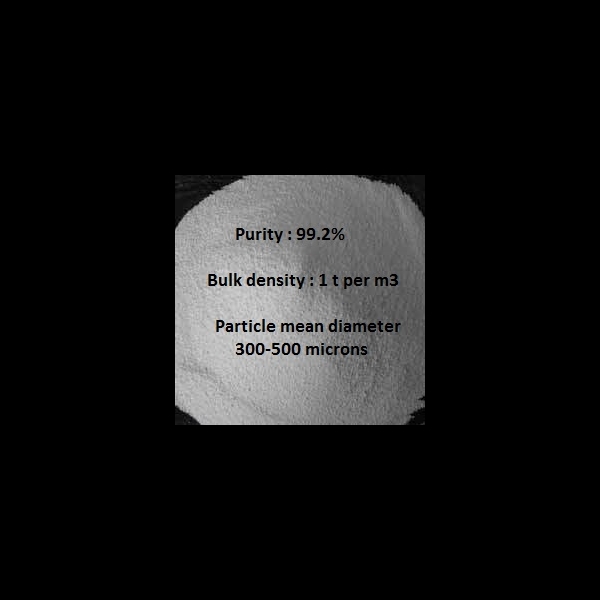

Soda ash is the trade name of sodium carbonate, Na2CO3. It is a white hygroscopic powder present in both hydrous and anhydrous forms. It is usually available in three grades: light, medium and dense. The difference lies in the physical characteristics of the chemical such as bulk density, particle size and shape.

Manufacturing Process

Solvay Process: It is one of the widely used manufacturing process for the production of soda ash. Sodium chloride and ammonia are bubbled through towers forming ammoniated brine. This is followed by carbon dioxide obtained from calcination of limestone and sodium bicarbonate is formed. Soda ash is obtained by the calcination of bicarbonate at 160-200 degrees. The bicarbonate is separated from ammonium chloride which is stripped off the ammonia and recycled back to the bubbling tower. The overall reaction is as follows: 2 NaCl + CaCO3 → Na2CO3 + CaCl2

Leblanc Process: Sodium carbonate is produced form salt and sulphuric acid. Firstly, salt is heated with the acid to form sodium sulphate. This is crushed with limestone and coal to obtain sodium carbonate and calcium sulphide. It is separated from the the ashes by washing with water. However, it is not used now since the hydrochloric acid produced posed major pollution problems.

2 NaCl + H2SO4 → Na2SO4 + 2 HCl

Na2SO4 + CaCO3 + 2 C → Na2CO3 + 2 CO2 + CaS

Hou’s process: Sodium bicarbonate is obtained from the treatment of ammonia with carbon dioxide to form ammonium bicarbonate and further treated with sodium chloride.

NH3 + CO2 + H2O → NH4HCO3

NH4HCO3 + NaCl → NH4Cl + NaHCO3

The bicarbonate is then heated to produce sodium carbonate.

Manufacturing Process

Solvay Process: It is one of the widely used manufacturing process for the production of soda ash. Sodium chloride and ammonia are bubbled through towers forming ammoniated brine. This is followed by carbon dioxide obtained from calcination of limestone and sodium bicarbonate is formed. Soda ash is obtained by the calcination of bicarbonate at 160-200 degrees. The bicarbonate is separated from ammonium chloride which is stripped off the ammonia and recycled back to the bubbling tower. The overall reaction is as follows: 2 NaCl + CaCO3 → Na2CO3 + CaCl2

Leblanc Process: Sodium carbonate is produced form salt and sulphuric acid. Firstly, salt is heated with the acid to form sodium sulphate. This is crushed with limestone and coal to obtain sodium carbonate and calcium sulphide. It is separated from the the ashes by washing with water. However, it is not used now since the hydrochloric acid produced posed major pollution problems.

2 NaCl + H2SO4 → Na2SO4 + 2 HCl

Na2SO4 + CaCO3 + 2 C → Na2CO3 + 2 CO2 + CaS

Hou’s process: Sodium bicarbonate is obtained from the treatment of ammonia with carbon dioxide to form ammonium bicarbonate and further treated with sodium chloride.

NH3 + CO2 + H2O → NH4HCO3

NH4HCO3 + NaCl → NH4Cl + NaHCO3

The bicarbonate is then heated to produce sodium carbonate.

Price

Negotiable

Contact with supplier